It usually happens at least once each winter, a day when temps get warm enough to justify rolling the bike out of the living room and take it for a frigid ride. Yesterday was such a day but it was special. Temps have been above normal all week and the roads are clear of snow and ice. We were set to break a record 50 degree high and those of us that ride were excited!

I slept in till dang near seven thirty. I knew there was no reason to rush things as there would still be over night refreeze of melted snow piles that wash across the roads. After going through my morning ritual, pushing the bike out the front door was no big deal and took only a few minutes. I cleaned up a small oil spot on the wooden floor and we rearranged the living room furniture to "summer" mode.

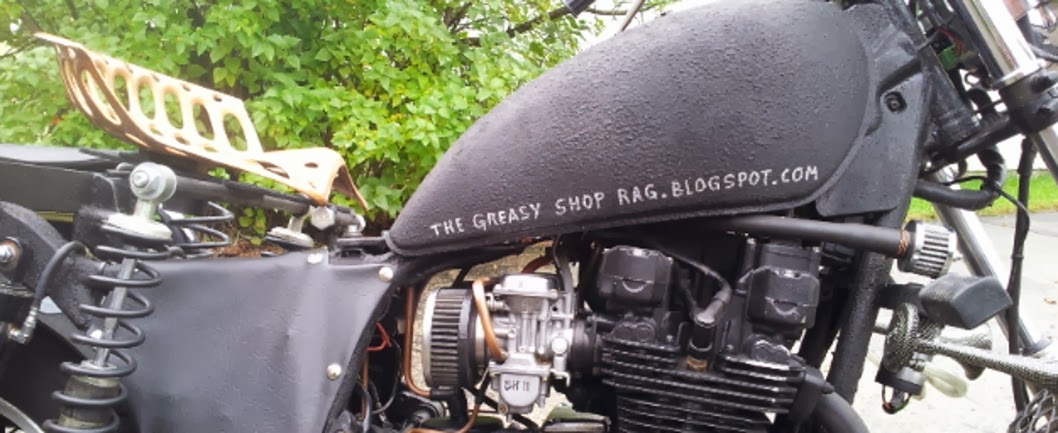

The bike got the usual once over to include fluid levels, air pressure and such. The only issue was a sticky carb float that fixed itself with a little persuasion from a hammer. After the bike was warmed up I threw a leg and started rolling away. As I pulled out of my drive I noticed a realtor across the street giving me a dirty look as a family was getting out of their car to look at the house for sale. All eyes were on me for some reason and this would have been a good place for a smokey burnout or wheelie, but as I stated in January, I was gonna try to be less of a dick head this year and I thought about that as I gingerly accelerated away.

The bike ran pretty good for a 28 year old machine and hauled me about ten miles before I remembered I only added a splash of fuel that morning. While at the gas station another patron commented about how unusual it was to see a bike out in February. I looked at the boat he was towing and told him the same could be said about his boat and asked where he thought he was gonna float that thing today. He chuckled and said it was going to the dealer to be traded in. I quickly suggested he trade it in on a bike because it was a beautiful day for a ride. That didn't go over well as he stated he'd seen way too many people die on bikes. I wasn't in the mood for his debbie downer bullshit so I just commented that I'd bet the cause of death to those bikers was probably never from drowning. I thumbed the starter and rode off, I mean wtf? Nobody ever died in a boating accident?

A quick stop for a selfie and to check ice conditions.

It was pretty obvious I wasn't getting across that heave on the sporty. Good thing because I needed an excuse not to go out and do something stupid.

I guess the sporty gobbled up much of that tank of fuel as I wandered around three counties just enjoying the bright sunshine. I stopped a few times just to stretch and kick some mud around. It was nice to step on some soil that wasn't frozen.

I had been sick all week and was just starting to feel better and didn't want to jeopardize that, so I found myself at home earlier than expected. While dinking around in my shop, my wife came in and announced that a wall hanging had fallen and we needed a new sticky-back hanger. The nearest hardware store is almost twenty miles away so...back on the bike!

Later.