Last week I got a call from a customer looking for a quote on a small job. It seems they had a rain gutter problem.

I think these gutters are supposed to be heated. For some reason this one seems to be a problem every year. The cones are there because there is a city sidewalk buried somewhere under that ice.

I ran the SkyTrac while co-worker James ran a pick axe. Shortly after these power wires were exposed he switched to and electric jack hammer. Once the gutter was exposed we started chipping away at the huge layer of ice on the sidewalk. All the ice chunks were pushed to the street then plowed away with a truck.

It was a lot of work but the end result was worth it. I hope it doesn't freeze over again because this job kinda sucked. Its tough working on ice when you are creating little ice chips that just make things more slippery. I landed on my ass once and James took at least three diggers.

This is going down as one of the coldest winters on record. Sure it looks sunny in these pics but the temps were in the single digits. I'm ready for spring and looking forward to that first ride of the year.

Wednesday, February 26, 2014

Sunday, February 23, 2014

Mama Tried

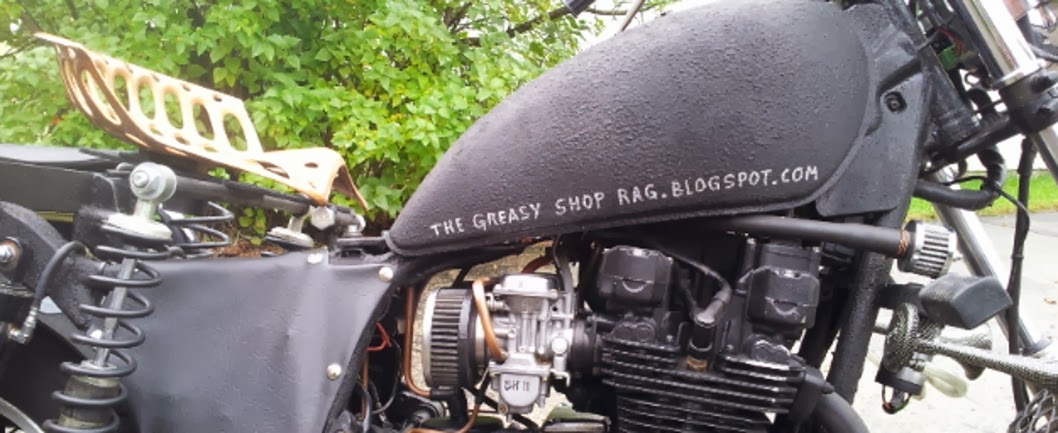

So yesterday I made it down to Milwaukee to the Mama Tried motorcycle show.

There was a good representation of bikes there. Something for the dirt, track, ice and street. There were a couple really old bikes and a few show bikes but I think most everything there was ridden or raced on a regular basis. Of course the chopper scene was well represented.

I was excited to see a lot of bikes that I was actually familiar with from following their owners blogs. I don't know these people but I did meet a few. I also met Brandon shown here on the right.

Brandon and I know each other from vacationing with a group at the BuRP rally a few years in a row. The last time we saw each other was about seven years ago. We hadn't talked about meeting at the show so he was surprised to hear from me. Pleasantly I hope. We spent a couple hours catching up and talking bikes. Its funny how a separation of seven years really doesn't change things. I mean a lot of things have happened to each of us in that time but we got along just like we've been hangin together all that time. The bikes were great but the time spent BSing with Brandon was what made the day for me.

About the bikes. Ya know I sit in my little shop and dream up stupid ideas then apply them to a bike. What I was reminded of is paint. I'm not a good painter but saw a lot of cool paint work. As a budget builder I realize I need to step up my game in the paint department.

There was a good representation of bikes there. Something for the dirt, track, ice and street. There were a couple really old bikes and a few show bikes but I think most everything there was ridden or raced on a regular basis. Of course the chopper scene was well represented.

I was excited to see a lot of bikes that I was actually familiar with from following their owners blogs. I don't know these people but I did meet a few. I also met Brandon shown here on the right.

Brandon and I know each other from vacationing with a group at the BuRP rally a few years in a row. The last time we saw each other was about seven years ago. We hadn't talked about meeting at the show so he was surprised to hear from me. Pleasantly I hope. We spent a couple hours catching up and talking bikes. Its funny how a separation of seven years really doesn't change things. I mean a lot of things have happened to each of us in that time but we got along just like we've been hangin together all that time. The bikes were great but the time spent BSing with Brandon was what made the day for me.

About the bikes. Ya know I sit in my little shop and dream up stupid ideas then apply them to a bike. What I was reminded of is paint. I'm not a good painter but saw a lot of cool paint work. As a budget builder I realize I need to step up my game in the paint department.

Wednesday, February 19, 2014

Workshop Wednesday-Evening Edition

So my post this morning was all about a fuse that was cracked. It hid itself pretty good and was difficult to find that problem. JT posted he had seen that before so maybe its not as uncommon as I thought.

Today I was working on another fork lift when co-worker Steve came over and asked me to help him diagnose a wiring issue on a Blizzard snow plow.

I welcomed the challenge and began telling him about my wiring nightmare yesterday. His wiring harness looked pretty good. Pliable wires with good insulation. He had the same issue where you could wiggle the harness and get different results. There was a inline two fuse holder and I pulled one of the fuses just to see. It was good. He pulled the other one and this is what he found:

It seems kinda weird that we found this same problem on two different pieces of equipment two days in a row, er no? At least I only lost half an hour looking for the problem. I think Steve got burned a bit worse.

There once was a broken down plow truck

The gremlins were winning and had us quite stuck

We were starting to lose

Till we found a bad fuse

Now I'll always look there first and maybe have good luck.

Today I was working on another fork lift when co-worker Steve came over and asked me to help him diagnose a wiring issue on a Blizzard snow plow.

I welcomed the challenge and began telling him about my wiring nightmare yesterday. His wiring harness looked pretty good. Pliable wires with good insulation. He had the same issue where you could wiggle the harness and get different results. There was a inline two fuse holder and I pulled one of the fuses just to see. It was good. He pulled the other one and this is what he found:

It seems kinda weird that we found this same problem on two different pieces of equipment two days in a row, er no? At least I only lost half an hour looking for the problem. I think Steve got burned a bit worse.

There once was a broken down plow truck

The gremlins were winning and had us quite stuck

We were starting to lose

Till we found a bad fuse

Now I'll always look there first and maybe have good luck.

Workshop Wednesday-Short Fuse

Nothing happened on my bikes since sunday. Monday was a 15 hour day in the truck pushing snow and tuesday was a bit more plowing and then I spent some time working on a fork lift. This particular fork lift is a repeat customer...as in I fixed it for a "no start" problem last week with a tune up. The machine has over 32,000 hours on it and the cap and rotor may have been original. Well probably not but they were bad. Cap, rotor, plugs and wires and she ran great. We trailered it back to the customer but the next day we got a call. "No start". This time it was a starter issue. The nose cone broke off the starter. I replaced the starter and noticed the flex plate seemed to move out of center just a bit. There were no cracks or loose bolts in the plate so it went back together. Yesterday I got a call..."no start". Ru ro Shaggy, I thought, but this time it was an issue where you would turn the key and nothing happened.

I threw some tools in a box and headed over there. Jump the starter, cranks fine. Turn key to start, dash lights change so I assume key is good. No power at solenoid so I'm thinking seat switch or neutral switch. Huh, no seat switch. I'll just run the test light over all the fuses to make sure the basics are covered. Yep, all test ok.

Man the insulation is crap on this wire harness. Cracked and brittle with some wires exposed. I spend an hour replacing some junk wiring and found a pair of loose wires twisted together just hangin there. Must have been for a seat switch. I sorted those out and I thought I was onto something because now she cranks! I'll just try it again to be sure...no crank. Huh. Holding the key in start position and wiggling the wire harness proved to me there was an intermittent connection somewhere. Good luck finding it. I was having flash backs to last year when a similar problem kicked my ass. Hard.

I tried separating as many sections of the harness as possible to pin point the area where the break was. This can be frustrating but after about half an hour of dinkin around I discovered the problem. I discovered it because I rechecked everything and what I found was this:

Are you freakin kidding me? When the wire harness was flexed just right that little broken section of fuse was making contact. When it flexed the other way the fuse acted like it was blown. Of course when I checked it the first time it was acting normal.

I walked out to my truck, opened the fuse panel and stole a 10 amp fuse. I put it in the forklift and all my troubles were gone.

Back at the shop Al told me a story about a plow light problem he had recently with a similar fuse issue. I know I've seen this before but its not something you think about when doing tests on a electrical system with so many crappy wires and years of different repairs and splices in the harness.

So what did we learn here? Nothing really. I could say that to assume only makes ans ASS out of U and ME but really when trying to quickly diagnose a problem like this a little assuming is in order. Only after no other problem is found should we go back and confirm all those assumptions.

Tomorrow they're calling for more snow to hit the ground,

I'll spend the day pushing it around.

Next time a fork lift gremlin is giving me the blues,

I'll be sure to double check every fuse!

Er no?

I threw some tools in a box and headed over there. Jump the starter, cranks fine. Turn key to start, dash lights change so I assume key is good. No power at solenoid so I'm thinking seat switch or neutral switch. Huh, no seat switch. I'll just run the test light over all the fuses to make sure the basics are covered. Yep, all test ok.

Man the insulation is crap on this wire harness. Cracked and brittle with some wires exposed. I spend an hour replacing some junk wiring and found a pair of loose wires twisted together just hangin there. Must have been for a seat switch. I sorted those out and I thought I was onto something because now she cranks! I'll just try it again to be sure...no crank. Huh. Holding the key in start position and wiggling the wire harness proved to me there was an intermittent connection somewhere. Good luck finding it. I was having flash backs to last year when a similar problem kicked my ass. Hard.

I tried separating as many sections of the harness as possible to pin point the area where the break was. This can be frustrating but after about half an hour of dinkin around I discovered the problem. I discovered it because I rechecked everything and what I found was this:

Are you freakin kidding me? When the wire harness was flexed just right that little broken section of fuse was making contact. When it flexed the other way the fuse acted like it was blown. Of course when I checked it the first time it was acting normal.

I walked out to my truck, opened the fuse panel and stole a 10 amp fuse. I put it in the forklift and all my troubles were gone.

Back at the shop Al told me a story about a plow light problem he had recently with a similar fuse issue. I know I've seen this before but its not something you think about when doing tests on a electrical system with so many crappy wires and years of different repairs and splices in the harness.

So what did we learn here? Nothing really. I could say that to assume only makes ans ASS out of U and ME but really when trying to quickly diagnose a problem like this a little assuming is in order. Only after no other problem is found should we go back and confirm all those assumptions.

Tomorrow they're calling for more snow to hit the ground,

I'll spend the day pushing it around.

Next time a fork lift gremlin is giving me the blues,

I'll be sure to double check every fuse!

Er no?

Sunday, February 16, 2014

Bright Idea

It doesn't feel like mother nature is gonna let up much and give us an early spring but I'm feeling the pressure as the weeks go by. When I pulled the sportster into my little workshop I thought it would be the first of three bikes I was gonna work on this winter. Its now obvious to me that its the only bike I'm gonna work on this winter. I don't know why I'm feeling rushed, I'll ride the rat turd in early spring anyway before all the salt is washed from the roads. Thats the nice thing about having a bike painted in truck bedliner...salt really isn't much of a problem.

I have the rear section of the sportster done. Sissy bar, tail lights, fender and license plate lighting. I also found a place for the air horn. The wiring for all this will terminate under the seat. I still need to add an outlet for my heated vest but thats no big deal.

I've been looking at the wiring mess up front. My goal is to clean that up a bit. I plan to accomplish this by moving the idiot lights off the speedo mount, maybe running the turn signal wires through the headlight housing and terminating the connections under the tank rather than at the steering neck like it is now. I'll run an extra wire up the handlebars for future accessories. I also want to get some heated grips so I can't move forward on that wiring until I order them. I'm still undecided which style I want to go with.

I've always said that if you don't ride at night then you're missing out on half a days worth of riding. For that reason I try to come up with the best lighting possible. The 5 3/4" light on it right now is cute but belongs on a bar hopper. I've had good luck with HIDs so right now I'm leaning toward a single 7" HID headlight. I'm hoping it will be a good balance between style and function.

I see that the kits now offer slim ballasts. I want to cram the ballast and igniter both into the headlight housing. I'm not sure they will fit but I'm prepared to introduce my used yamaha headlight housing to my cut-off wheel. I'll make it fit.

I'll get a kit ordered here soon and post the results. Meanwhile I really need to clean my little work shop. I was considering more shelves but what I really need is less stuff.

I have the rear section of the sportster done. Sissy bar, tail lights, fender and license plate lighting. I also found a place for the air horn. The wiring for all this will terminate under the seat. I still need to add an outlet for my heated vest but thats no big deal.

I've been looking at the wiring mess up front. My goal is to clean that up a bit. I plan to accomplish this by moving the idiot lights off the speedo mount, maybe running the turn signal wires through the headlight housing and terminating the connections under the tank rather than at the steering neck like it is now. I'll run an extra wire up the handlebars for future accessories. I also want to get some heated grips so I can't move forward on that wiring until I order them. I'm still undecided which style I want to go with.

I've always said that if you don't ride at night then you're missing out on half a days worth of riding. For that reason I try to come up with the best lighting possible. The 5 3/4" light on it right now is cute but belongs on a bar hopper. I've had good luck with HIDs so right now I'm leaning toward a single 7" HID headlight. I'm hoping it will be a good balance between style and function.

I see that the kits now offer slim ballasts. I want to cram the ballast and igniter both into the headlight housing. I'm not sure they will fit but I'm prepared to introduce my used yamaha headlight housing to my cut-off wheel. I'll make it fit.

I'll get a kit ordered here soon and post the results. Meanwhile I really need to clean my little work shop. I was considering more shelves but what I really need is less stuff.

Wednesday, February 12, 2014

Random Rat

I like rat bikes. I like to see what an owner will do in a pinch to keep a machine on the road. It doesn't matter if it's a temporary fix or a permanent solution on a budget. All rats, survival bikes and Dark Customs interest me. Old piece of crap or purpose built rats get the same praise from me. I like the bikes that make you think. Whats that do? Is that real or fake? Does this piece actually do anything? Where's the ____?

Here's a bike I have seen the last few years at the Slimey Crud Run. I don't know anything about the owner but I like the way he thinks.

Check out the custom built front end. I did notice when he came to a stop the front end dove pretty hard so I'm not sure how well this bike actually handles. This pic is two years old so he may have done some work on it to fix that problem. No matter, I applaud him for building something original.

Here's a bike I have seen the last few years at the Slimey Crud Run. I don't know anything about the owner but I like the way he thinks.

Check out the custom built front end. I did notice when he came to a stop the front end dove pretty hard so I'm not sure how well this bike actually handles. This pic is two years old so he may have done some work on it to fix that problem. No matter, I applaud him for building something original.

Sunday, February 9, 2014

Old Honda in a Shed

Last night my wife and I went to her employee appreciation party. We used to call these things Christmas parties, then Holiday parties. They also used to be held in December. Anyhow, things change. After the party some of her friends wanted to go bar hopping. We don't hop. I don't even walk very good lately.

I don't remember what the attraction was to standing in a bar full of strangers having to shout to the person next to you because its so loud in there. We were packed in there elbow to elbow and couldn't even move around. The only time I can remember being that crowded was back in basic training when they stuffed us into the cattle trucks to move us around the base.

Before the party we discussed not missing the bar scene. Last night we confirmed it. Oh sure, I had some fun at the party but I can think of more productive ways to spend my time. One thing that won't change is the fact that I'm getting old(er).

So the other day I was digging through some pics and was surprised when I found this old Honda.

I barely remember owning this bike. I know that's the inside of my shed. That cooler looks familiar and I still have that crappy old ladder. I just don't remember much about the bike. I know it didn't run and wasn't registered but I can't remember where it came from.

Too bad I got rid of it because its just what I need for a project I want to do. You know, a stripped down minimally equipped cafe racer style bar hopper. Of course I won't use it for actual bar hopping but I think it would be a fun project. Something will come along.

I don't remember what the attraction was to standing in a bar full of strangers having to shout to the person next to you because its so loud in there. We were packed in there elbow to elbow and couldn't even move around. The only time I can remember being that crowded was back in basic training when they stuffed us into the cattle trucks to move us around the base.

Before the party we discussed not missing the bar scene. Last night we confirmed it. Oh sure, I had some fun at the party but I can think of more productive ways to spend my time. One thing that won't change is the fact that I'm getting old(er).

So the other day I was digging through some pics and was surprised when I found this old Honda.

I barely remember owning this bike. I know that's the inside of my shed. That cooler looks familiar and I still have that crappy old ladder. I just don't remember much about the bike. I know it didn't run and wasn't registered but I can't remember where it came from.

Too bad I got rid of it because its just what I need for a project I want to do. You know, a stripped down minimally equipped cafe racer style bar hopper. Of course I won't use it for actual bar hopping but I think it would be a fun project. Something will come along.

Wednesday, February 5, 2014

Workshop Wednesday-Just a lot of whining

Workshop Wednesday, well this last week has been a bit of a bummer. Last week I reported I would be building a new fert spreader/spray rig. After discussing our needs and goals with the boss it was decided that we would just buy a new one. Sure, new equipment is cool but so is building one from scratch.

In other workshop related news I have been fixing a lot of fork lifts lately. Fork lifts are a pain in the ass to work on. There's a lot of crap stuffed in a small space and they are low to the ground dirt magnets.

I had to dig a couple of graves last week. Its easy enough work but it always gets me thinking about how many years I may or may not have left.

Then two days ago I got some kind of bug that completely liquefied the contents of my intestines. I made it just over halfway to work before it was decided going to work was a bad idea. I continued on only because that bathroom was closer than turning around and heading home. I arrived at the shop, took care of business and headed back home where I spent the day in bed and the bathroom. I can't remember the last time I took a sick day from work.

It was a one day thing. Yesterday I picked up a bucket of chicken and all the fixins. No problems.

On top of all that, the day I was sick was my wifes birthday. She didn't get the special treatment that she deserves. I'll have to come up with something special to make it up to her.

I'm done whining.

In other workshop related news I have been fixing a lot of fork lifts lately. Fork lifts are a pain in the ass to work on. There's a lot of crap stuffed in a small space and they are low to the ground dirt magnets.

I had to dig a couple of graves last week. Its easy enough work but it always gets me thinking about how many years I may or may not have left.

Then two days ago I got some kind of bug that completely liquefied the contents of my intestines. I made it just over halfway to work before it was decided going to work was a bad idea. I continued on only because that bathroom was closer than turning around and heading home. I arrived at the shop, took care of business and headed back home where I spent the day in bed and the bathroom. I can't remember the last time I took a sick day from work.

It was a one day thing. Yesterday I picked up a bucket of chicken and all the fixins. No problems.

On top of all that, the day I was sick was my wifes birthday. She didn't get the special treatment that she deserves. I'll have to come up with something special to make it up to her.

I'm done whining.

Sunday, February 2, 2014

Wrap it up

I have been looking for something to wrap the wires for the tail lights and license plate lights on the sportster. Actually I have been looking for a few weeks now. I didn't want to have to buy anything because I knew there must be something laying around. My problem was that I was looking for an actual wire protection product. When I started just looking for anything that would work my search quickly became successful.

For the license plate lights I wanted something that would fit over the 1/4" hollow bolt that the wires come out of. I found what I needed but had to figure out how to harvest it.

Its an old control cable from a snow blower. The thin plastic sleeve covering the metal spiral cable housing looked like it would be perfect but how was I gonna get it off of there?

It turns out that if you clamp the metal housing in a vise and start stretching, the plastic cover slides right off. That five foot cable had about forty feet of spiral wound wire that was stretched out of the covering.

I pushed the covering over the wires and onto the bolt on the back of the light. Then I put a small piece of heat shrink tubing over it to make it a little neater. It makes a clean water tight seal to protect the wires.

The tail lights were done in a similar fashion except I needed a larger diameter covering so I used an old extension cord. I clamped the wires in a vise and pulled the cover off just like I did with the control cables. No pics because its just as boring as the last three photos.

This all seems simple enough but until I found the covering for the wires, I couldn't do any of the wiring on the bike. Once I get these routed and wired under the seat I can start working on the rats nest of wires near the steering neck.

For the license plate lights I wanted something that would fit over the 1/4" hollow bolt that the wires come out of. I found what I needed but had to figure out how to harvest it.

Its an old control cable from a snow blower. The thin plastic sleeve covering the metal spiral cable housing looked like it would be perfect but how was I gonna get it off of there?

It turns out that if you clamp the metal housing in a vise and start stretching, the plastic cover slides right off. That five foot cable had about forty feet of spiral wound wire that was stretched out of the covering.

I pushed the covering over the wires and onto the bolt on the back of the light. Then I put a small piece of heat shrink tubing over it to make it a little neater. It makes a clean water tight seal to protect the wires.

The tail lights were done in a similar fashion except I needed a larger diameter covering so I used an old extension cord. I clamped the wires in a vise and pulled the cover off just like I did with the control cables. No pics because its just as boring as the last three photos.

This all seems simple enough but until I found the covering for the wires, I couldn't do any of the wiring on the bike. Once I get these routed and wired under the seat I can start working on the rats nest of wires near the steering neck.

Subscribe to:

Posts (Atom)